20th May, 2021

We interviewed Dick Elsy about the Catapults journey so far, overcoming challenges – most recently COVID-19, the fear of failure and his advice for the future of the innovation landscape.

Dick Elsy has been CEO of High Value Manufacturing Catapult for 8 years and during that time has made major contributions to the sector. He will be handing over his post to Katherine Bennett, former Senior Vice President at Airbus.

Dick spent the bulk of his career with Land Rover and then Jaguar. At Land Rover, he became a member of the Board and led the creation, development, and manufacture of the Freelander. Dick is a fellow of the Royal Academy of Engineering and a holder of its Silver Medal. In 2018 he was awarded a CBE in recognition of his contribution to manufacturing and technology in the UK. In 2020, Dick chaired the VentilatorChallengeUK consortium, a collection of significant industrial and engineering partners from across the UK which manufactured and delivered over 13,000 ventilators for the NHS during the COVID-19 pandemic.

We asked Dick Elsy several questions about his journey with the Catapults.

Here is what he said:

You have been a part of the Catapult development from its early inception with the High Value Manufacturing Catapult (HVM) being the first Catapult to be founded. Tell us a bit about that journey?

It was just getting out of the starting blocks when I joined as the first CEO in 2012. People think that HVM Catapult was fully formed, bringing seven independent already existing centres together to establish the Catapult, but in reality, only 3 centres had any real track record at all. The Advanced Forming Research Centre (AFRC) and the Manufacturing Technology Centre (MTC) only opened their doors to businesses in 2010, so they were right at the beginning. Then the National Composites Centre (NCC) opened their doors in 2011 and the Nuclear Advanced Manufacturing Research Centre (Nuclear ARMC) in 2012.

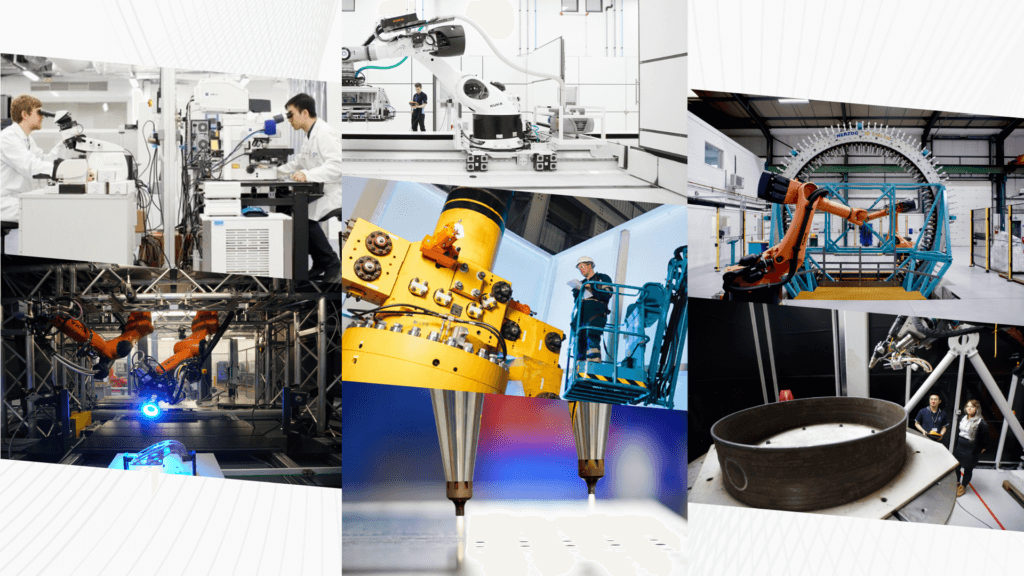

We had lofty ambitions with only £30m a year but from that we went on a remarkable journey, establishing the seven centres and now we are the largest advanced manufacturing research institute in Europe. In those early days, we aspired to be like the Fraunhofer Institutes almost as if that was an unreachable goal because Germany had been working on it for 70-odd years. But to get to where we are now in 10 years from a standing start, in particular when manufacturing was not at the forefront of British psyche, publicly and with politicians, to be in that position is quite a remarkable achievement. We already have a very good international reputation.

There must have been so many barriers and challenges you had to face. What were the most difficult you can recall?

Setting up a Catapult from scratch is always a chicken and egg challenge. There is core funding that comes as a grant from Government which is helpful to develop capability, resources, kit, equipment, people and to keep the lights on, but ultimately you must create an offer that is sellable to industry. So, it does take quite a bit of time and effort to build credibility in order to secure projects with industry. It is fine when the Catapult is mature but in the early stages and early days, of course it really is hugely challenging. And then the sponsor, whether it is Innovate UK and UK Government, wants instant results. It is difficult.

I think that by being an asset-based Catapult – in other words, we have cutting edge advanced manufacturing equipment, people who know how to use it, smart engineers, and a firm collaboration model – it is a very tangible offer. People quickly understood it and there was a strong appetite from industry. I think it has been tougher for some of the other Catapults who have more of a service-based offer and therefore had to demonstrate their added value very quickly, but still with great success.

There is a huge appetite within all the Catapults because we are working on some great things together as a Network, like a big Net Zero campaign. We are all joining forces to convene this much broader capability to take on these big challenges where no other institutional arrangements are in place to do so.

You came from an industrial background yourself, were there things that you were able to take from your industrial history into the Catapult development?

Definitely! I have faced the challenge of bringing risky new technology to market. Looking back through my career as a young man in the mid-eighties I was involved in a super high-risk, winner-takes-all-or-fail programme called Original Discovery which was a make-or-break programme for Land Rover. It could not be done under normal circumstances because it would take too much money and take too long. So, a group of maverick thinkers were put inside a portacabin to solve that challenge. It was a fantastic experience. I used that experience again on Freelander, another breakthrough programme, which saw a set of whiteboard notes convert itself to the engineering of £12bn of new added value to the UK economy. The impact it made on the national and regional economy was extraordinary to experience.

Then, in my later career working in a very complex and advanced technology, which was in typical valley of death territory, where brilliant concepts and proven prototypes and the whole question of ‘could this be industrialised and scaled up?’ became familiar challenges. When the opportunity to run the Catapult and to help do that on a national level came up, it was too good to miss, but it came off the back of visceral experiences of dealing with technology.

Another example emblazoned on my mind, comes from my time at Jaguar. I led the transition from steel-based bodies of cars into aluminium and it was a technology which had been developed by Ford in the States in their labs, but it wasn’t at the right implementation level. It was gifted on Jaguar to take through into production and it was very challenging because the technology wasn’t sufficiently mature. If we’d had a Catapult in those days I would have used it but, as we didn’t, I was having to prove it out in real time in a production environment. That was tough.

We made our way through it, but it illustrates that it is very risky to introduce new technology. The whole concept of the Catapult, that is helping to share and bear that risk, is critically important. Having seen first-hand what it means to be right at the edge of that risk, has made me such a profound supporter of the Catapult programme.

A new part of your CEO role in addition to technology was the need to interact with Government. Any reflections on that?

I thought that would be the part of the job that I would find the most difficult and probably least enjoy. But actually, over the last 8 and a half years, it is the part of the job that I have enjoyed and been stimulated by more than anything. Ministers face some real tough challenges. So, I asked myself, how can we engage with Ministers with this incredibly powerful instrument – the Catapult programme – make it work for them, give them what they need, and help the nation, and all move forward together. Winning the hearts and minds of new Ministers, new civil servants and trying to get them on side with what we are doing, understand what we are doing, I found the journey really interesting. But it has not been automatic. Many times, I have had to sell our story and the HVM Catapult from first principles, but that goes with the territory – and what a great story to tell.

I asked myself, how can we engage with Ministers with this incredibly powerful instrument – the Catapult programme – make it work for them, give them what they need, and help the nation, and all move forward together.

If you were to look back at the point when you moved over from industry into the Catapult, would there be a piece of advice that you would give yourself?

I think it took me some time to recognise that you haven’t got a conversation unless you can prove that you are impactful: What are you actually going to deliver? So, I am very conscious now in asking for something that I ought to give Government real tangible evidence-based reasons to do it. None of these things can be a given. That would be a key lesson.

How do you think the Catapult has done through the Covid-19 crisis and how has it worked to use its power of innovation to the good?

We were involved in one of the key actions to help the pandemic with VentilatorChallenge UK, responding to a crisis where we didn’t have enough intensive care ventilators and Government said we need them now. Motorsport, aerospace, automotive and medical devices all rallying together to do that. It was just an amazing thing to do, but very reflective of the convening power of the Catapult. All those companies felt they could take that corporate risk because of their affiliation with the HVM Catapult, a trusted institution they knew and had worked with, which was a big enabler to get everybody on side.

The principles of collaboration – team working and all the things we hold dear in our Catapult – were just borne out in grand scale in the ventilator challenge. Those kind of exemplary behaviours of people, pulling resources and capability, the stop-at-nothing culture, was just terrific to see. It was basically like the Catapult model but just on speed.

When you set the right environment up, empowering people to do the right thing, minimal bureaucracy and no heavy-handed oversight, it is amazing what you can achieve. One of the key learning points for me was that you can achieve so much more by being nimble. One of the perceived down sides of course of empowering people to do the right thing and letting them loose, is that you could lose control of everything. Again, within the Ventilator Challenge it couldn’t be more opposite. Although we handled an emergency, we delivered the Penlon ventilator for £9.5k each and usually an intensive care ventilator is about £18k. So why wouldn’t you do everything like that? What stops us from putting our best people together on challenges? Fully empowered, transparent reporting, no heavy-handed management. People like working that way.

Within the wider Catapult Network, the Cell and Gene Therapy Catapult stepped up to support the vaccines when we critically needed their support and then of course with our Centre for Process Innovation we’ve got an advanced vaccines’ mutation capability, so we are keeping one step ahead of the virus, which is fantastic.

There has been some very interesting learning from the crisis – that of putting greater resilience in place. Resilience in terms of vaccine capability and to be able to mitigate mutation and variants, but also from an industrial perspective where we are seeing quite a strong appetite to maintain manufacturing capability in the UK for strategic reasons. We are seeing a change of attitude – a realisation that its actually important to make a few key critical things ourselves. We’ve got the technical capability to do it and we appear now to have the commercial willingness to do it as well.

What else have you learned from this experience to manage a big and important project at pace?

We’ve been highlighting the learnings with our friends in Cabinet Office who of course went through the journey with us, and that led to us advising some big infrastructure programmes. We were also invited to give a masterclass to Ministers that were involved in large projects, which went down extremely well. The importance of convening institutions, industry and academia around big challenges has also helped to shape the new strategy for HVM Catapult where we are looking not just to do more of the same but step up into some of the big national challenges. With the target of 78% of the emissions reduction by 2035 now proposed in law, the only way that we are going to get there is by delivering some serious amounts of innovation. There is a huge appetite within all the Catapults because we are working on some great things together as a Network, like a big Net Zero campaign. We are all joining forces to convene this much broader capability to take on these big challenges where no other institutional arrangements are in place to do so.

There are many ways in which Catapults individually and as a Network are coming together to answer some of the big questions. In the HVM Catapult we have a lot happening in low carbon transport, the circular economy, reducing pollution, low carbon energy. Cell and Gene Therapy Catapult is developing vaccine tools, Offshore Renewable Energy Catapult is developing the next generation of renewables and it goes on.

Do you think Government is using Catapults enough?

No. We’ve had our heads down delivering and I think we need to be working more on our messaging and explain what we are doing. The recent BEIS review of Catapults very strongly says, ‘great instrument, you need to use more of them’. I don’t feel we are embedded enough in UKRI’s thinking, bearing in mind that they are our sponsoring body. Some of the right people at Innovate UK understand us but not enough. So, there is a job of work to be done there. We are sitting on this fantastic instrument that is not well enough understood, and for me, with the challenges that we are now facing, we’ve got to be responding clearly and effectively with what our offer is.

In the 8 ½ years of my tenure in the Catapult we’ve seen some great examples of impact, particularly regionally. Take a look at Sheffield and Rotherham, an incredible journey that was started by Keith Ridgway where the Orgreave Coke Works developed into a gleaming advanced manufacturing park, not just a park doing the research, but also attracting inward investment from blue-chip companies like Boeing, McLaren, Rolls-Royce with its advanced blade casting. A cluster of top-notch ultra-high value industries coming to Sheffield. That then of course stimulated plans to further build that out with more high-tech capability. What an incredible blue touch paper to light!

MTC started out as a group of portacabins in late 2009. There is now £800m worth of inward investment in and around the MTC. Think about what has happened in the North East with CPI and all the stimulus that has happened there, Darlington now being at the centre of vaccine developments. Wonderful!

We’ve had our heads down delivering and I think we need to be working more on our messaging and explain what we are doing. The recent BEIS review of Catapults very strongly says, ‘great instrument, you need to use more of them.’

Ten years in, are the things that businesses are coming to Catapults for changing?

I think some of the scale of what we are doing is increasing, we are taking on bigger and bigger projects. To be of use to customers we’ve had to set up full pilot production facilities. A great example is at NCC and the Wing of Tomorrow programme with Airbus where we are laying down 17m lengths of carbon fibre robotically, resulting in machines the size of a semi-detached house. It is jaw dropping in scale. Also, the desire to help as many SMEs as possible is driving us into helping micro-SMEs with their innovation challenges. I think there is probably a frustration of not having enough bandwidth to get to as many SMEs as possible and put the resources in place. We’ve been activists in doing that. I’ve put funding in place since the early days of HVM Catapult to make sure we always had space to cater for SMEs.

In what ways are Catapults supporting SMEs?

When Manufacturing Advisory Services got pulled in England, which I think we all lament, I never wanted us to be a proxy for that, but in reality, in order to get SMEs to innovate you’ve got to win their hearts and minds, so part of our route into the mind of an SME is to just help them with some basic things to show that thinking differently can have a big impact

Rather than offering SMEs something complicated and technical, often our centres have sent their people to visit their premises to see how they operate, and they spotted some low hanging fruit. It might just be that the goods receiving needs to be laid out in a different way because they have a bottle neck and addressing that has provided a big productivity improvement. Then often the SME comes for another bite and moves into something a little bit meatier.

When you set the right environment up, empowering people to do the right thing, minimal bureaucracy and no heavy-handed oversight, it is amazing what you can achieve. One of the key learning points for me was that you can achieve so much more by being nimble.

There is a known fear of failure in innovation – what do we do about it, how do we address that low-risk culture that emerges?

That is one of the biggest barriers of all. That is why the Catapult programme is so good, because it shares in that risk. It puts experienced people who have been around the block a few times sitting alongside you to guide you through the challenges. Taking a risk on your own is a lonely thing to do. For SMEs, buying the wrong piece of kit without looking at the complete picture, could bring the company down. That’s why the Catapult model works so well. The innovation element is an important one, but with SMEs it is not always a critical factor. It is not technology that necessarily is the answer, thinking differently is the answer.

One thing that I have noticed over the years is how tradable innovation and technology is between sectors. I was brought up as an automotive person and I found myself propelled into aerospace and other sectors. Solutions developed in one sector are very transposable to others. So, one thing with the HVM Catapult is that the development of solutions, and having those on the stocks for redeployment, has been a hugely enriching thing for the UK. We support 4000 companies a year and when you aggregate all of that know-how and knowledge together across sectors, it is extraordinary, and this rich seam of knowledge is available to support British companies.

With things like battery technology, there is a sense that different solutions are required by different sectors but when you actually boil it down, we are all just looking for the same thing. Businesses want high power density, high energy density, batteries that last for ages and they want them to be crash proof and cheap. Because we are in a neutral convening position, we make those conversations between sectors so much easier. Engineers talk a common language anyway, but we really help break down barriers, so much so that other sectors look to us to help. And we’ve got the best help there with the battery team at WMG.

There is a great example in the construction sector where collaboration is normally characterised by litigation when things go wrong. Wafer thin margins, projects late and big challenges to face. Aerospace and automotive have got their act together – first of all in their process to deliver – but also in their collaborative activities in the UK. So, we helped the construction industry put a collaborative programme together, helped it win a sector deal and now MTC and Clive Hickman (CEO) and his team are running the construction and innovation hub, bringing all that learning in aerospace, automotive, rail and marine to construction.

What do you think has been your proudest moment in all of this journey?

The thing I am most proud of is the regional impact. To see real added value, jobs, factories, and particularly apprentices and young people. We know that the AMRC Boeing is equipped with people who have been through the AMRC process. Young people running that factory who may not have had opportunities before but have fantastic things lying ahead of them. It is really great to see it. The MTC with their commitment to training, managed to get Lloyds Bank to sponsor apprenticeships. There is a lad that has gone on to Mercedes Formula 1. Fantastic!

And there’s NMIS the National Manufacturing Institute for Scotland as the anchor point for a gleaming new advanced manufacturing park just next to Glasgow Airport. Real levelling up -not just words.

Are there people that stand out to you on the journey that you travelled?

Lots. There’s been 19 CEOs across the 7 HVM centres. It has been an incredible journey with them and really rewarding. Bringing new people in and at each stage being enriched. Pulling the new strategy together with the CEOs has been a real reflection of the level of maturity that we’ve now reached. But notable people that it all wouldn’t have been possible without, I would mention Iain Gray, in the golden era of Innovate UK or the TSB as it was. Ian’s vision to get behind the Catapult programme, to get it set up and to make sure he chose people well. He clearly thought through that quite carefully. Will Barton also working to get the Catapult programme set up. Simon Edmonds, who of course is still there, and put his all into supporting us. All important people who really understood the model. To be honest, I want us to get back to that place in terms of intimacy, we need a strong Innovate UK and for us to be really understood as the instrument of translation.

What excites you most about the HVM Catapult’s future and the future of the whole Network?

It’s our tenth anniversary this year since HVM Catapult was founded. The model is now mature and it can be very effectively measured. The Catapults have been through a full review with BEIS that says we are a really good thing to have. For me, and I am slightly reluctant to be leaving because it’s a real “planets align” moment, we need this burgeoning requirement for innovation, not just scientific endeavour, and we need it translating into tangible results to decarbonise the economy. That is not going to happen on its own. We need innovation delivered, big time, in the next 10 to 15 years and you have a perfect instrument in the Catapult Network. Combined, we are the major force perfectly positioned to step up and deliver.

If you had one do and one don’t for Government over the next two or three years, what would they be?

Recognise the power of the thing you’ve got right in front of you and use it well. It’s fine having ambition, but you’ve got to deliver it. You’ve got to put the arrangements in place and as we’ve seen with the Catapults it’s taken quite a few years for the thing to get up to speed, to develop itself, to gain trust and to develop its models. It has proven it works. What you don’t do, and this sounds really tough – you don’t do heavy handed bureaucratic oversight. That is an absolute killer for innovation.

Recognise the power of the thing you’ve got right in front of you and use it well. It’s fine having ambition, but you’ve got to deliver it.

Any other advice would give to Government in making the UK a strong innovation economy?

We are only of use as a science superpower if that translates itself to economic and societal benefit. If all we do is double the number of learned papers, it’s great for the academic community but it’s not going to advance our position in the world other than the academic world. We’ve got to deliver societal and economic benefit. We’ve faced some very recent health challenges, where engineering, manufacturing and science has come to the rescue, and they will come to the rescue again for global warming. We’ve got to deliver innovation and there are precious few delivery mechanisms in place to translate the science through to application. The other thing I would say to Government is if you are putting money into science and innovation, make sure that it is targeted. You must get industry to say ‘these are solutions we need – we need batteries that do this, we need carbon sequestration that does this’ – and start to drive the research from an industry perspective.

Any final words?

The selection of the right people for the right time in the programme. That is one of the reasons I am very happy to be stepping back and handing over to Katherine Bennett. I think she is a great choice and is going to be perfect for the HVM Catapult. It all boils down to people.

We wish to thank Dick Elsy for sharing his wealth of experience during this interview and most importantly, for his significant contributions to the Catapult Network. We wish him the very best of success in all future endeavours.

Ends